/ INVENTED IN THE UK

British engineering at its best.

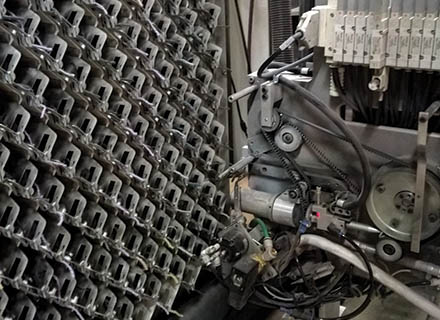

High speed Axminster production.

The innovative High Speed Axminster machine has been developed and honed by a team of experienced engineers and carpet makers. This machine is 3x faster than traditional axminster looms and 20 percent faster than its closest competitors.

THE TECHNOLOGY

The loom consists of both smart and fixed creels. The smart creels are robotically operated and use exactly the right amount of yarn for each job providing an 80% reduction in yarn waste. This enables orders to be woven one after the other.

Reduced re-creeling time combined with the use of a bullet over a traditional shuttle system contribute to making the process 60% more time efficient.

The perfect combination of high quality New Zealand wool and high quality manufacturing equipment means less yarn breakages and less down time. This unique technology results in a more efficient and less labour intensive production line.

SPECIFICATION

A Cut Pile Axminster with yarn composition of 80% Wools of New Zealand and 20% Nylon. Pitch: 7 Rows: 9 Carpet Width: 12ft